SE-6 Series Speed Control Quantifiable Rubber Belt Feeder Scale

I. Product Summary

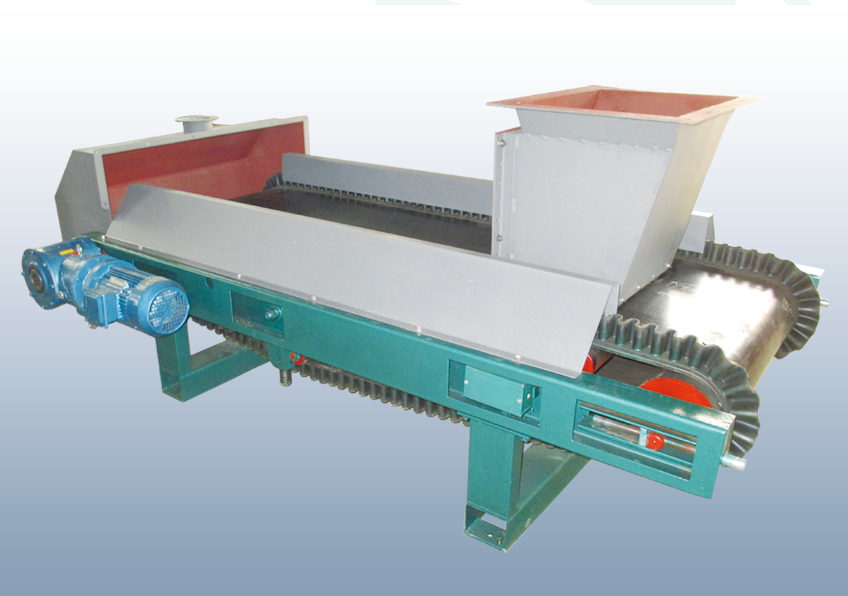

The SE-6 Series Speed Control Quantifiable Rubber Belt Feeder Scale is an equipment for the continuous conveying, dynamic weighing, quantified feeding and ingredient control of bulk, granular and powdery materials. It is widely used in fields like building, metallurgy, mining, chemical industry, light industry, etc. It is especially an ideal choice for equipment like mills, kilns, dryers in cement factories.

II. Structure and Features

The SE-6 series consist of belt conveyor, transducer and a SE-51 weighing controller developed by us. Belt and feeding speed are smoothly adjusted by the transducer within a short response time.

Basing on the customers’ need, we can provide transducers of well-known brands—M420 series of Siemens or EV1000 series of Emerson.

No matter the transducer and weighing controller are equipped with one or multiple belts, we will provide integrated control cabinet for our customers. The cabinet’s functions include operation mode selection, feeding speed monitoring, accumulation display, alarm, closed loop control, communication, etc. The control cabinet can be connected to an industrial control computer or a DCS and constitute an SE-01 ingredient control system.

Basing on the customers’ need, we can provide transducers of well-known brands—M420 series of Siemens or EV1000 series of Emerson.

No matter the transducer and weighing controller are equipped with one or multiple belts, we will provide integrated control cabinet for our customers. The cabinet’s functions include operation mode selection, feeding speed monitoring, accumulation display, alarm, closed loop control, communication, etc. The control cabinet can be connected to an industrial control computer or a DCS and constitute an SE-01 ingredient control system.

III. Control Cabinet Dimension

Scale with 1 belt: 500W×700H×250Dmm

Scale with 2-9 belts: 800W×2000H×650Dmm

Scale with 2-9 belts: 800W×2000H×650Dmm

IV. Specifications

◇ Dynamic measuring accuracy: ≤±0.5% (relative error between 20% and 100%)

◇ Control Accuracy: ≤1.0%

◇ Conveying Capacity: 0.1~250 t/h

◇ Material granularity: ≤60 mm

◇ Belt Width: 650, 800, 1000, 1200 mm

◇ Belt Speed: 0.006~0.248 m/s

◇ Speed Control Range: 10:1

◇ Motor Power: 0.75~2.2kw

◇ Control Accuracy: ≤1.0%

◇ Conveying Capacity: 0.1~250 t/h

◇ Material granularity: ≤60 mm

◇ Belt Width: 650, 800, 1000, 1200 mm

◇ Belt Speed: 0.006~0.248 m/s

◇ Speed Control Range: 10:1

◇ Motor Power: 0.75~2.2kw

V. Scale Body

The scale body consists of belt conveyor (rack, motor and gearing, apron rubber belt), scale receptor, weight sensor and speed sensor. Based on the study of the advantages and disadvantages of various belt scales, this new scale body we have developed possess the following advantages: its installation, configuration and maintenance are easy and convenient, and it is steady and durable, with high precision and reliability.

◇ The scale body uses double-row self-aligning bearing instead of cross-shape plate spring

◇ The scale body roller has a double-channel enclosed structure including a stuffing sealing element and a metal dust-proof sealing cap.

◇ A spring tensioning wheel is used instead of gravity tensioning.

◇ Auto correction device

◇ The apron annular non-joint belt prevents materials from spilling.

◇ A direct-connection motor—reduction gears specifically designed for Schenck scales.

◇ The weight sensor can be dismounted alone easily.

◇ The non-contact magnetic speed sensor has a high precision and short response time.

VI. Scale Dimensions

◇ The scale body uses double-row self-aligning bearing instead of cross-shape plate spring

◇ The scale body roller has a double-channel enclosed structure including a stuffing sealing element and a metal dust-proof sealing cap.

◇ A spring tensioning wheel is used instead of gravity tensioning.

◇ Auto correction device

◇ The apron annular non-joint belt prevents materials from spilling.

◇ A direct-connection motor—reduction gears specifically designed for Schenck scales.

◇ The weight sensor can be dismounted alone easily.

◇ The non-contact magnetic speed sensor has a high precision and short response time.

VI. Scale Dimensions

Scan QR Code to Follow Seagle's WeChat Page

Jiangsu (Nanjing) Strong Eagle Automation Engineering Co., Ltd.

Add.:Room 2101, Building 01, Zhongtai International Plaza, 313 Jiangdongzhong Road,

Nanjing, Jiangsu Province, China

P.C.: 210019

Tel.: +86 (025) 52339281 87783181

87783182 87783183

Fax:+86 (025)87783184

Web.:www.njseagle.com

Email:seagle@vip.163.com