SE-LDICS Cement Loading & Delivering Intelligent Control System

I. Product Summary

By adopting interface technology and secondary development & integration, our company perfectly combines SE-LDICS Cement Loading & Delivering Intelligent Control System with SE-LIMS Logistics Information Management System for Cement Enterprises and Intelligent Inkjet Printer Control System. By unifying the management of the loading information of bagged cement packages, ICS for Cement Loading and Shipping realizes the count and auto-loading of bagged cement packages. At the same time, it also prints the manufacture (package) date and serial number of the cement. The system has been widely acclaimed by the customers by increasing the cement loading efficiency and avoiding industrial risks.

By adopting interface technology and secondary development & integration, our company perfectly combines SE-LDICS Cement Loading & Delivering Intelligent Control System with SE-LIMS Logistics Information Management System for Cement Enterprises and Intelligent Inkjet Printer Control System. By unifying the management of the loading information of bagged cement packages, ICS for Cement Loading and Shipping realizes the count and auto-loading of bagged cement packages. At the same time, it also prints the manufacture (package) date and serial number of the cement. The system has been widely acclaimed by the customers by increasing the cement loading efficiency and avoiding industrial risks.

II. Major Components

Loading Control Server

Loading Industrial Control Equipment

Loading Machine

Inkjet printer

Card Reader

LED Screen etc.

Loading Control Server

Loading Industrial Control Equipment

Loading Machine

Inkjet printer

Card Reader

LED Screen etc.

III. System Components

SE-LDICS Cement Loading & Delivering Intelligent Control System contains:

1. Logistics Management System

2. Intelligent Loading Control System

3. Intelligent Inkjet Printer Control System

SE-LDICS Cement Loading & Delivering Intelligent Control System contains:

1. Logistics Management System

2. Intelligent Loading Control System

3. Intelligent Inkjet Printer Control System

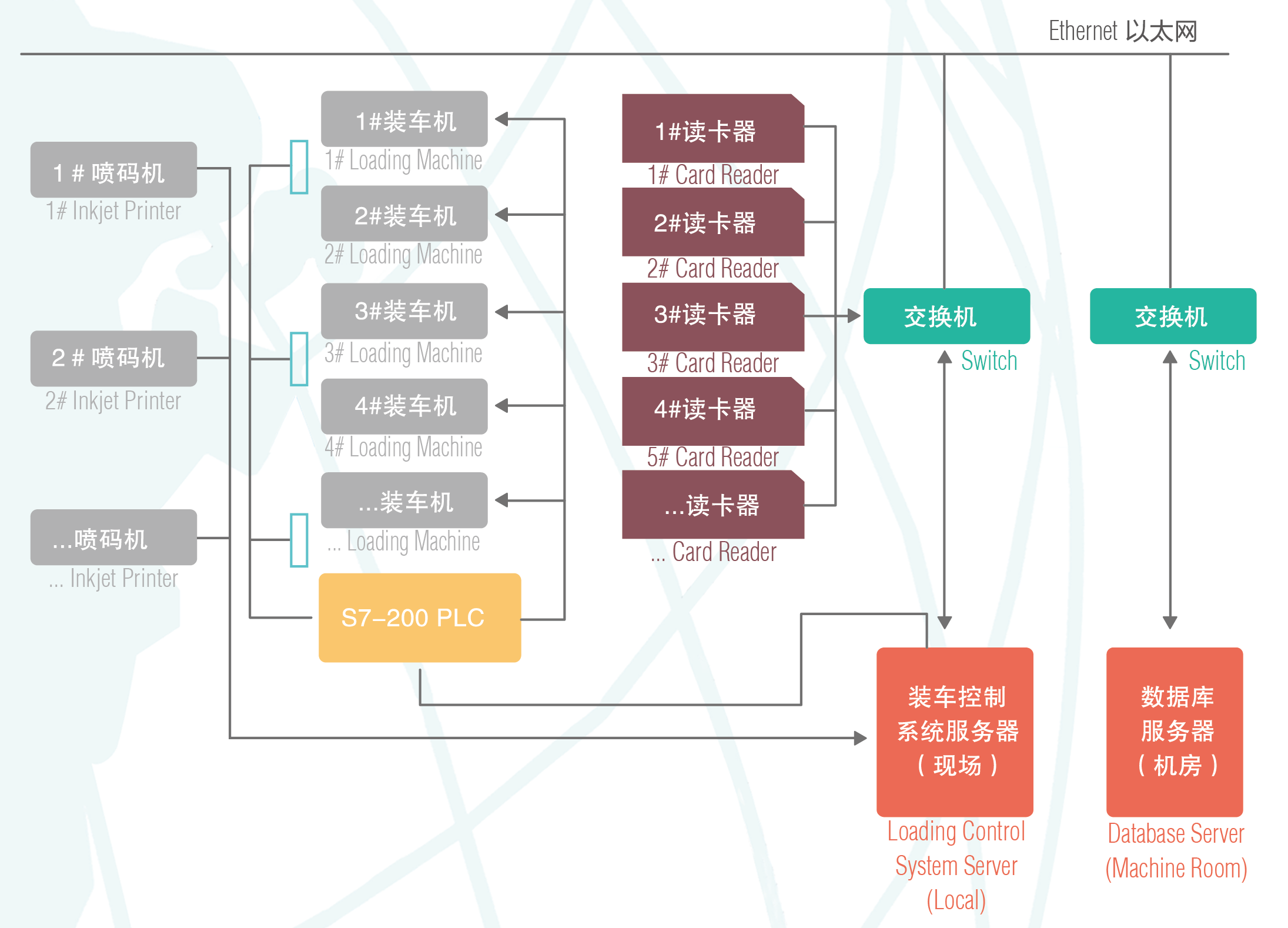

IV. System Principles

V. Module Structure

Module structure of SE-LDICS Cement Loading & Delivering Intelligent Control System follows by:

1. Factory Numbering Processing Module

2. Card Number Receiving and Processing Module

3. Spray Loading Control and Timeout Control Module

4. LED Display Control Module

5. Inkjet Printer Control Module

VII. Product Benefits

1. Increase both drivers and customers’ satisfaction, and save drivers’ time by leaving out middle procedures in goods picking up process during selling distribution.

2. Control the loading category of each channel to avoid loading the wrong category;

3. Control the power of each loading channel through the system, and unauthorized or faulted vehicle cannot be loaded;

4. Automatic registration of loading: Automatically control the manufacturing serial number of each vehicle accordingly, meanwhile, automatically change the printed information of the SQ/2 ink-jet printer instead of manually changing to increase the efficiency and precision of loading; the printing information can be customized specifically based on its license plate, customers’ information, etc. to prevent commodities fleeing.

5. It can prevent possible mistakes by displaying real-time loading information through the LED electronic display screen for loading and on-site management personnel; while it can also provide the driver with accurate species and loading information.

6. It can improve the efficiency of regulation and control by providing real-time loading information from each channel and the factory number of each variety for the lab and field management staff.

Scan QR Code to Follow Seagle's WeChat Page

Jiangsu (Nanjing) Strong Eagle Automation Engineering Co., Ltd.

Add.:Room 2101, Building 01, Zhongtai International Plaza, 313 Jiangdongzhong Road,

Nanjing, Jiangsu Province, China

P.C.: 210019

Tel.: +86 (025) 52339281 87783181

87783182 87783183

Fax:+86 (025)87783184

Web.:www.njseagle.com

Email:seagle@vip.163.com