SE-LIMS Cement Logistics Information Management System

I. Product OverviewIndependently researched and developed by our company, SE-LIMS Cement Logistics Information Management System comprehensively includes systems of internal resource management, financial management (interface), supply chain management, customer relationship management, knowledge management, business intelligence and monitoring center. The System realizes the solution of centralized management and control, unified scheduling among multiple bases, respective shipping by each production base and independent accounting of multiple financial departments. By building SE-LIMS, we form the ability of quality management with real-time enterprise characteristics, management of logistics information and management of data. Consequently, we can improve the management level of production with higher pertinence and then promote the core competence of enterprises.

After building LIMS, we can seamlessly integrate business planning and field operations, realizing all the process including the visual management of planning and scheduling, purchase sales, process control, abnormal monitoring, which also avoid information isolation and build the Enterprise digital information closed loop system. At the same time, combined with real time monitoring system, we create an integrated and solid control system of managing logistics quality. In this way, we realize the multi directional monitoring, analysis and improving of site, personnel and quality. At the same time, the system also satisfies the flexible control request of enterprises and makes manufacturing logistics quality fined, transparent, automated, real-time, with data and integrated.

The system has been successfully operating in a number of large domestic cement companies, obtaining a wide range of users’ praise.

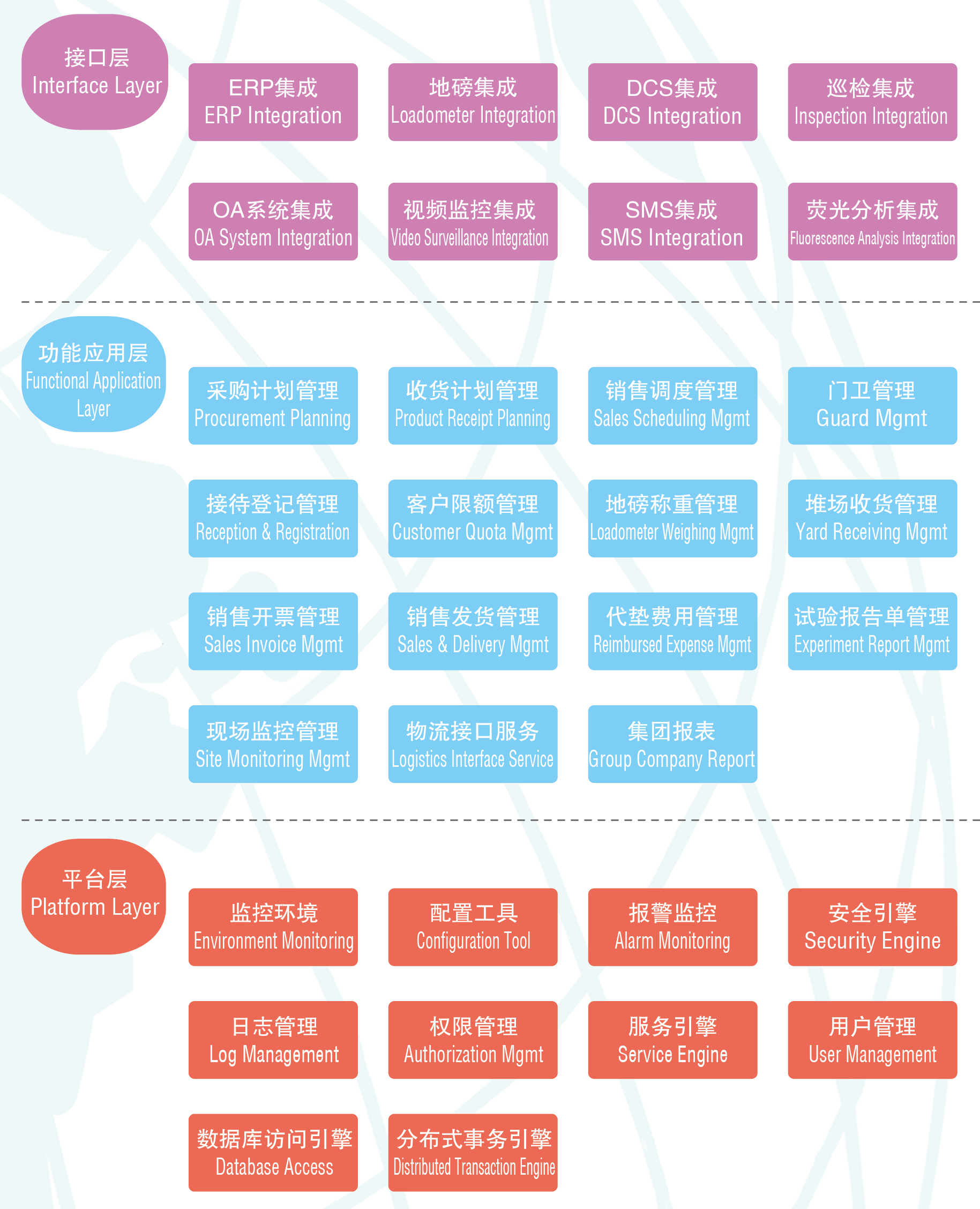

II. System Modules

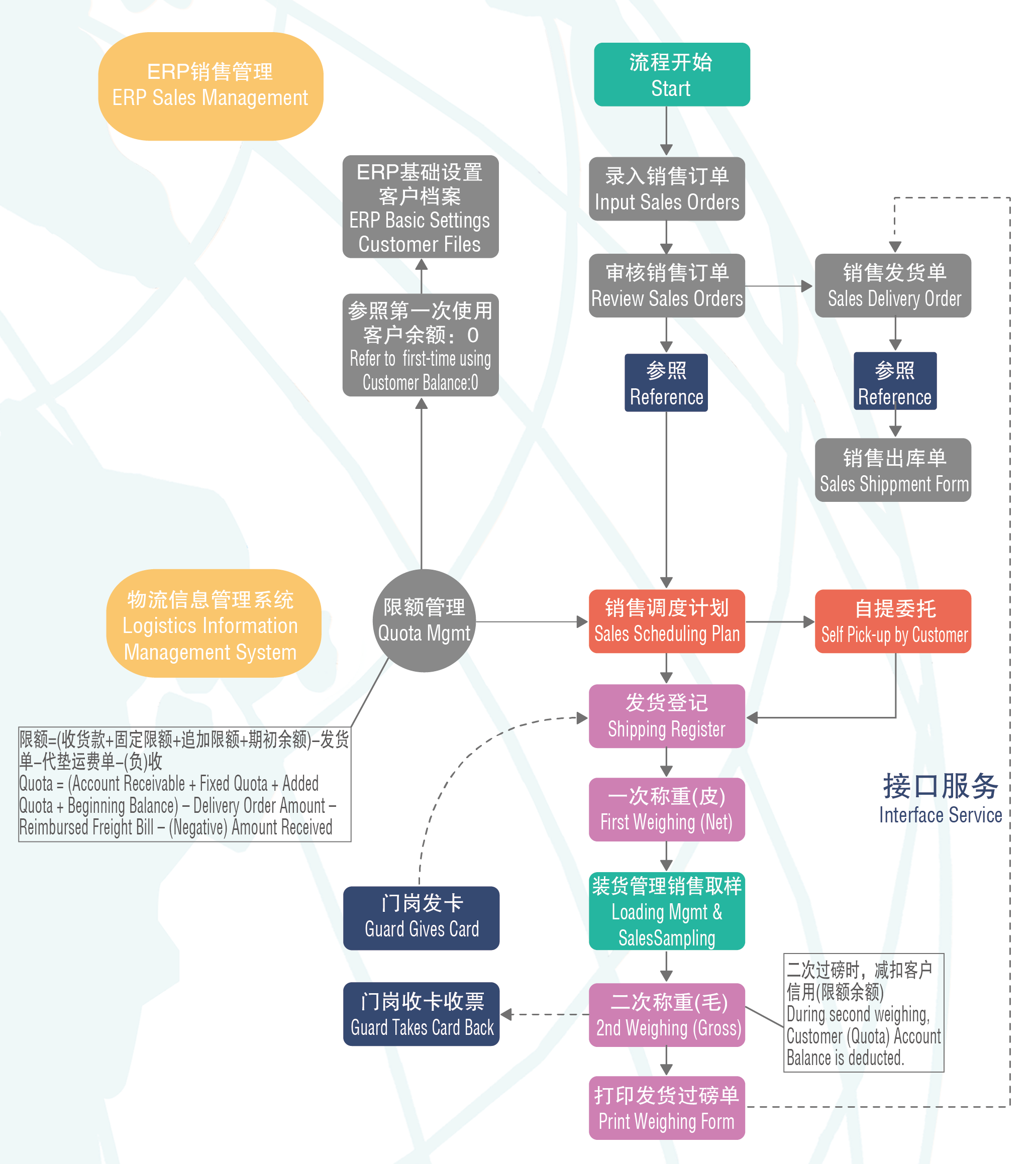

III. Process Illustration

IV. System Advantages

1. The system supports various management modes for company or company group with single plant, multiple plants, multiple production bases, or multiple production lines.

2. It is specially designed for six major categories of users in the cement industry, including engineering customers, mixing station customers, construction and real estate customers, oil system customers, broker customers, or retail customers. The system supports multiple sales settlement methods, for example cash settlement, monthly payment and so on, which strengthens the management and control of sales settlement, payment, and cement delivery. This would help users to avoid the risk of bad debt.

3. It provides flexible pricing strategies on cement, which supports the cement price to fluctuate along with market changes.

4. It tightly integrates the sales delivery schedule with vehicle schedule planning, improving the co-processing capability of sales and logistics process.

5. It offers one-stop management of automatic freight calculation, collection and payment, and the subsidies and its payment.

6. It provides professional quality management and control system of cement industry, achieving the printing of 3-day or 28-day cement experiment report and quality traceability.

7. It provides system integration and data sharing with company’s weighing (Loadometer), One Card Pass, and Golden Tax systems or services.

8. It is able to integrate company’s pound room system and factory security monitoring system. In addition, it can also provide corresponding interfaces to ERP system, realizing the goal of resource sharing.

9. The integrated platform achieves group company’s overall operations, data analysis, production and security monitoring, and enterprise reporting.

Scan QR Code to Follow Seagle's WeChat Page

Jiangsu (Nanjing) Strong Eagle Automation Engineering Co., Ltd.

Add.:Room 2101, Building 01, Zhongtai International Plaza, 313 Jiangdongzhong Road,

Nanjing, Jiangsu Province, China

P.C.: 210019

Tel.: +86 (025) 52339281 87783181

87783182 87783183

Fax:+86 (025)87783184

Web.:www.njseagle.com

Email:seagle@vip.163.com